Professional Laser Cleaning

Laser cleaning represents an innovative and advanced solution for removing residues and contaminants from various surfaces. Using the energy of a concentrated laser beam, this method allows you to clean selectively and precisely, without physical contact with the material to be treated.

This technique is based on the emission of a laser beam which, upon contact with the surface, generates a vaporization or sublimation action of the residues or impurities present. The process occurs in a rapid and controlled manner, thus ensuring high efficiency and minimal alteration of the base material.

Suitable for different materials, laser cleaning is particularly effective on metals, plastics, fabrics and even sensitive materials such as wood or glass. This makes it an ideal choice in various industrial fields, from machinery maintenance to the preparation of surfaces for welding or painting processes, up to the cleaning of cultural and historical assets.

Furthermore, the laser cleaning process is eco-sustainable, as it does not require the use of chemicals or solvents, reducing the environmental impact and risks to the health of operators. Its precision and ability to reach areas that are difficult to clean manually make it a cutting-edge technological solution in the industrial cleaning and restoration sector.

Thanks to its high precision laser beam, it allows you to join materials efficiently and with high quality.

This methodology has significant advantages compared to other traditional welding techniques. With a wide range of industrial applications, laser welding offers high flexibility and versatility.

Let’s discover its operating principles, materials and applications, procedures and techniques, systems and equipment, safety and precautions, as well as future developments that characterize it.

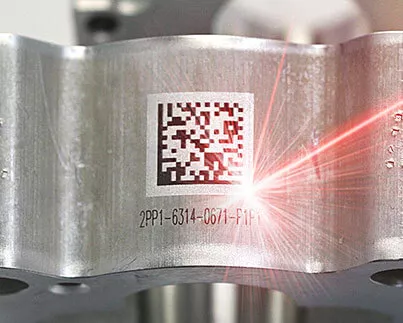

Laser cleaning machines are advanced devices designed to effectively remove contaminants and residues from a variety of surfaces. These systems use laser technology to generate a concentrated beam of light which, when directed on the surface to be cleaned, works by eliminating dirt, oxidation, paint or other types of deposits without damaging the underlying material.

These devices work through a process where the laser hits the surface, creating a thermal effect that removes dirt or unwanted coating. This technique stands out for its precision, allowing you to clean complex or delicate surfaces without the risk of abrasion or damage. The speed and power of the laser can be adjusted according to the type of material and the degree of dirt or oxidation to be removed.

Laser cleaning machines are used in various industrial applications, from the removal of rust and paint, to the preparation of surfaces for painting or welding processes. They are also used in the restoration of works of art and historical monuments, where delicacy and precision are fundamental.

In summary, laser cleaning machines represent a significant innovation in the field of industrial maintenance and restoration, offering an efficient, precise and environmentally friendly approach to cleaning various surfaces.

+39 800 821 577

sales@lasitlaser.com

Location

ITALY | Via Solferino 4, 80058

Torre Annunziata (NA) - Italy

POLAND | Ul. Fabryczna 34, 43-100

Tychy, Poland

SPAIN |

Calle Bari 55, 50197

Plataforma Logística Zaragoza

GERMANIA |

Im Stockäcker 7, 78194

Immendingen

REGNO UNITO |

Unit 6 Blythe Valley Innovation Centre

Central Boulevard

© 2024 LASIT Sistemi e Tecnologie Elettrottiche S.p.A. | P.Iva 02747991210 | C.F 01803670643 | Chi Siamo | Contattaci Privacy Policy.