Professional laser engraving machines and systems

Laser engraving is a process that uses a laser to create a precise, permanent engraving on a variety of materials, such as metals, plastics, wood and other materials.

The laser is focused on the surface of the material, where it emits an intense, concentrated beam of light that can remove material from the surface of the material.

Laser engraving can be used to create text, images or other designs on the surface of the material. The depth and width of the engraving can be controlled by adjusting the laser power and the speed of movement of the laser on the surface of the material. It turns out to be a precise and accurate process that is used in many industries, such as the electronics industry, watchmaking, jewelry and consumer goods industry.

Laser marking and laser engraving are both processes that use a laser to modify the surface of a material. However, there are some important differences between the two processes:

Depth: Laser marking leaves a shallow engraving on the surface of the material, while laser engraving can create deeper engravings.

Finish: Laser marking leaves a matte etch on the surface of the material, while laser engraving can leave a smooth or matte finish depending on the laser settings.

Accuracy: Laser marking is very precise and can produce high-quality engravings on the surface of the material. Laser engraving can be just as precise, but it depends on the laser settings and the material used.

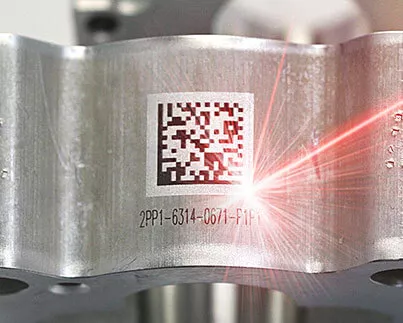

Usage: Laser marking is primarily used to mark material with identifying information, such as the serial number or company logo. Laser engraving, on the other hand, is used to remove material from the surface of the material to create designs, images or text.

In summary, laser marking is a process that leaves a shallow engraving on the surface of the material, while laser etching is a process that removes material from the surface of the material to create deeper engravings.

Engraving and marking are often used confusedly, as if they were the same thing. In reality, these are two contrasting manufacturing processes: although both can be used to create a permanent inscription on a material, the results of the two processes are different. To know more:

ENGRAVING: Engraving is the process of removing a part of the surface of an object. Different approaches can be used, including laser techniques, to permanently abrade the surface of the material and give it a coloration caused by the high temperature generated during the process.

MARKING: Marking refers to the transformation of the surface of a material which results in a lasting shade thanks to the interaction with a laser beam. With laser marking we are able to imprint a predetermined pattern.

The main distinction between the two procedures is how they interact with the material: etching requires removal of material, while transformation marking does not.

The use cases for these two processes are different and often mutually beneficial, however engraving is an essential part of craft and art, while marking is typically a commercial procedure used mostly in the industrial sector.

The cost of laser engraving can vary depending on several factors, including the type of material, the complexity of the design, the time required for engraving, and the type of laser machine used. However, due to the high efficiency and low labor required for laser engraving, it is often a more economical solution than other engraving methods. To obtain an accurate quote, it is advisable to contact the laser engraving service provider directly.

The laser engraving process involves using a laser beam to remove material from the surface of an object. The laser beam is guided by the computer to follow a precise path, determined by the design to be engraved. When the laser beam hits the material, it heats the surface, causing it to vaporize or melt. This creates a permanent etch on the surface of the material.

Lasers are extremely versatile and can cut a wide range of materials. These include different types of plastic, wood, paper, fabrics, leather, glass, ceramics, metals and many others. The ability of a laser to cut a particular material depends on the type of laser and the power of the laser beam. For example, fiber lasers are particularly effective at cutting metal

Despite their versatility, there are some materials that lasers cannot cut safely or effectively. These include highly reflective materials such as polished aluminum and copper, which can reflect the laser beam and cause damage to the laser machine. Other materials, such as PVC, can release toxic gases when cut with a laser and are therefore not suitable for use with this technology

Laser engraving is an incredibly versatile and powerful process that can provide precise, high-quality results on a wide range of materials. Its cost can vary, but its efficiency and accuracy often make it an economical choice for many applications. To determine if laser engraving is the right choice for your project, it’s important to consider the type of material, the desired design, and your specific needs.

info@bestlasermarking.com

Location

ITALY

POLAND

SPAIN

GERMANIA

REGNO UNITO

© 2026 Best LASER MARKING – MARCATORI LASER PROFESSIONALI | Contattaci Privacy Policy.